Liquefied Natural Gas (LNG): Technology, Economics, and the Mombasa Maritime Milestone

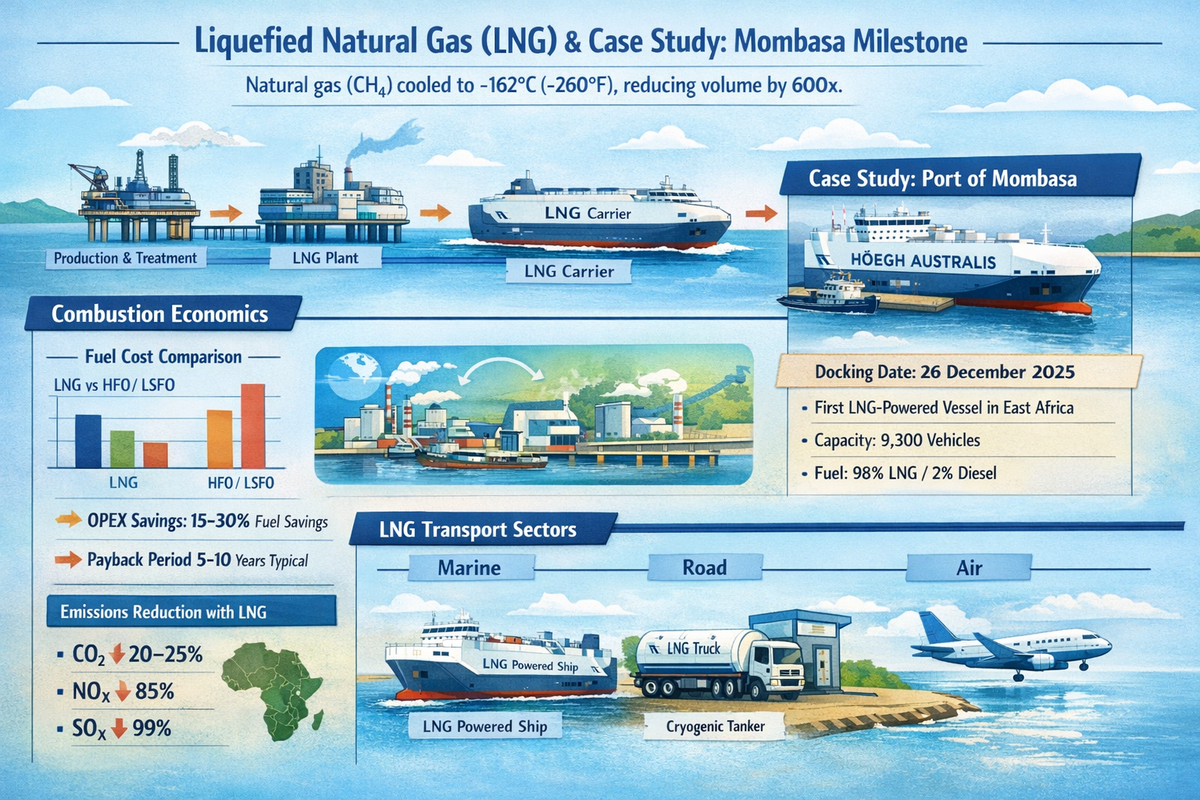

Liquefied Natural Gas (LNG) is natural gas (predominantly methane, CH₄) that has been cryogenically cooled to −162°C (−260°F) to convert it from gas to liquid. In liquid form, its volume is reduced by about 600×

1. Overview: What is LNG?

Liquefied Natural Gas (LNG) is natural gas (predominantly methane, CH₄) that has been cryogenically cooled to −162°C (−260°F) to convert it from gas to liquid. In liquid form, its volume is reduced by about 600×, greatly enhancing transport and storage efficiency especially for international trade where pipelines are not feasible.

Primary Benefits

- High volumetric energy density (liquid form) compared with gaseous natural gas.

- Enables global trade of natural gas across continents.

- LNG is cleaner than most fossil fuels: lower CO₂, SOx, NOx, and particulate emissions when combusted.

2. Physical & Chemical Properties of LNG

Composition

- Mostly Methane (CH₄) with trace ethane, propane, nitrogen.

- Virtually free of sulfur and contaminants that cause corrosion.

Key Properties

- Cryogenic liquid at near atmospheric pressure.

- Clear, non-toxic, non-corrosive in liquid state.

- LNG boil-off must be managed to control pressure in tanks.

3. LNG Logistics: Chain from Source to End Use

Typical Stages

- Production & Gas Treatment

- Clean & remove contaminants (CO₂, water) to prevent freeze-up.

- Liquefaction

- Multi-stage refrigeration cools gas to liquid.

- Marine Transportation

- LNG carriers with cryogenic tanks cross oceans.

- Regasification Terminal

- LNG warmed to gas and fed into pipeline or direct use.

- Distribution

- Pipeline, ISO cryogenic containers, trucks, rail.

4. LNG in Transportation Sectors

4.1 Marine Transport (LNG-Powered Vessels)

LNG has emerged as both a marine fuel (bunker) and the cargo itself.

A. LNG as Marine Fuel

- Ships can operate on LNG fuel (dual-fuel engines) reducing emissions significantly.

- IMO 2020 Sulphur Cap and future mid-century decarbonisation targets drive adoption.

- LNG reduces:

- Sulphur Oxides (SOx) nearly 99%

- Nitrogen Oxides (NOx) ~85%

- Carbon Dioxide up to ~23% or more depending on engine tech(MTCC Africa)

B. LNG as Cargo

- Carried by specialized LNG carriers in cryogenic tanks.

- LNG carriers are sized 125,000–266,000 m³ typically.

- Vast roll-on/roll-off (Ro-Ro) and container ships increasingly built with LNG bunker systems.

5. Case Study: Historic LNG-Powered Vessel at Port of Mombasa

5.1 Event Summary

- Vessel: Höegh Australis — a Norwegian-flagged Ro-Ro carrier.

- Date: Docked at the Port of Mombasa on 26 December 2025.

- Voyage: ~11 days from Singapore(Kenya News)

5.2 Vessel Capabilities

- Length: ~200 meters

- Beam: ~37.84 meters

- Decks: 16

- Capacity: ~9,304 vehicles

- Fuel: ~98% LNG, ~2% conventional bunker fuel (for start-up)(Kenya News)

5.3 Significance for Mombasa & Region

- First LNG-powered vessel to dock at any East African port — a major marine logistics milestone.(Kenya News)

- Demonstrates port readiness for green shipping aligned with Kenya Ports Authority’s Green Port Policy and global environmental standards.(African Climate Council)

- Signals strategic positioning of Mombasa as a future hub for low-emission maritime traffic.

5.4 Environmental Impacts

Compared to conventional bunker fuel ships:

- Lower emissions of CO₂, NOx, SOx, particulate matter.

- Aligns with the International Maritime Organization (IMO) and regional sustainability policies.(Kenya News)

6. Combustion Economics & Costs

6.1 Fuel Cost Comparisons

LNG vs Conventional Fuel (HFO/LSHFO)

- LNG often trades at competitive or lower cost per MMBtu depending on market and region.

- Shipping costs from producers (e.g., Qatar to Kenya) can be $0.50 per MMBtu lower than to some other regions due to shorter hauls (but varies with contracts)(PPP Knowledge Lab).

Typical Marine Fuel Cost Factors

- LNG price at bunkering point

- Taxes, port fees

- Bunkering infrastructure availability

- Vessel fuel consumption rates

- Engine efficiency and boil-off utilisation

6.2 Combustion Efficiency in Marine Engines

Dual-Fuel Engines

- Burn LNG and conventional fuel flexibly.

- LNG has lower volumetric energy than heavy fuels requiring more fuel volume.

- Lower particulate & sulfur emissions.

Boil-off Management

- LNG tanks generate vaporised gas (“boil-off”) that can be routed to the engine (fuel or gas-combustion units) to minimise losses.

7. Logistics Cost Drivers

7.1 Marine Logistics

- Ship acquisition/charter costs

- Bunkering infrastructure

- Port readiness and compliance

- Voyage distance and routing

- Charter rates (LNG vessels sometimes carry premium due to tech)

- Crew training & safety compliance

7.2 Road Transport

- LNG trucks require cryogenic tankers and handling systems.

- Higher CAPEX than diesel trucks, but lower fuel cost per km can improve ROI for heavy duty hauls.

7.3 Air Transport (Experimental/Support)

- LNG in aviation remains R&D and niche, not commercial.

- Cryogenic storage and infrastructure challenges limit adoption.

8. ROI Analysis Framework for LNG Shipping

Return on Investment (ROI) in LNG adoption depends on operational savings, capital cost differential, regulatory incentives, and fuel price dynamics.

ROI Factors

- CAPEX Differential: LNG engine installation vs conventional (higher upfront cost)

- Fuel OPEX Savings: Lower per-unit cost of LNG vs heavy fuel

- Regulatory Incentives: Emission compliance can save on penalties, access environmental corridors

- Residual Value: Vessel adaptability to future fuels (e.g., ammonia)

Simple ROI Model (Illustrative)

| Component | Estimated Effect |

|---|---|

| CAPEX premium for LNG engines (approx) | +15–25% of newbuild cost |

| Fuel savings per year (varies) | −10–30% (LNG vs HFO)* |

| Emission penalties avoided | varied |

| Payback period | Typically 5–10 years** |

*varies by region/fuel pricing; **indicative depending on utilization and contract structure.

9. Safety & Operational Considerations

Safety Protocols

- IGF Code governs onboard gas fuel systems.

- Special crew training and certification.

- Cryogenic handling procedures.

Operational Benefits

- Lower environmental risk than heavy fuels.

- Reductions in port penalties for emissions.

10. Strategic Implications for East Africa

Mombasa Port

- Increased readiness for greener, future-fuel vessels enhances competitiveness in regional logistics.

- Potential catalyst for future LNG demand in power and industrial sectors in Kenya (e.g., planned LNG import terminal studies).(The EastAfrican)

Regional Integration

- Could attract more carriers adopting LNG fuel.

- Reduces carbon footprint of regional trade corridors.

11. Summary: LNG & the Mombasa Milestone

- LNG logistics encompass production, cryogenic transport, and energy end-use.

- LNG as a marine fuel is gaining traction with environmental regulations and cost advantages.

- Höegh Australis docking at Mombasa marks a historic moment in East African marine logistics, demonstrating readiness to serve the next generation of eco-friendly shipping lines while supporting cleaner and more efficient international trade.(Kenya News)